Don’t wait until others have already given up before asking us. But don’t wait when they do.

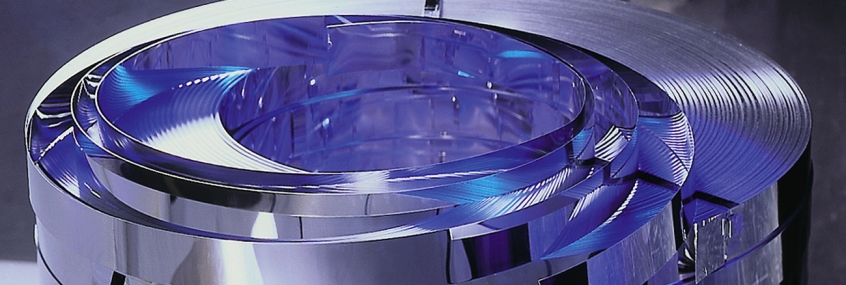

Rolled products for niche and special solutions. Small and medium tonnages. And of course standard products and large volumes, too. Our rolling mill in Meschede is a specialist for maximum mechanical qualities, surface grades and tightest tolerances – from development together with our customers up to production.

From our rolling mill we supply the automotive industry, the mechanical engineering, toolmaking and plant engineering sectors, as well as the consumer goods industry and trading. Our product range extends from coils, sheets and plates via sheet metal forming for automotive interiors up to decorative patterned surfaces for interior furnishings and band-anodized products.

Our product range in the plate segment includes, besides standard plates, also cut to fixed dimensions as required by the customer, as well as round blanks and special shapes. In sheet rolling, our product spectrum extends to strips, sheets and round blanks. Apart from standard alloys, we mainly supply gloss materials that are used for cosmetic containers or in automotive, e.g. for trim strips.

Particularly innovative and successful products are, for example, our sheets with decorative embossed surfaces. With an embossing roller we apply individual, decorative structures onto aluminium sheet to achieve specific gloss effects – for especially fine and durable applications in the premium segment. The “Honsel-Special-Plan” (H-S-P) plate has also been successful across Europe. Milled on both sides, this plate with very low intrinsic tensions, a finely grained and pore-free microstructure with very good mechanical properties and outstanding processability is used in many industrial applications.

Regardless, which shape the aluminium will assume, we can coat each of our products on both sides with foil.

We are also happy to take over the further manufacturing and punch or form the semi-finished product until it is ready for installation.

We prove our flexibility not only in our product portfolio, that includes standard as well as special shapes, but also in other areas. Delivery time, for example, is brought into line with the wishes and demands of our costumers.

In development, we support our customers with our profound materials and manufacturing knowledge. So we can guarantee that the semi-finished and finished products delivered are coming up to requested dimensions and display precisely the optical and mechanical properties needed for further processing and finishing or for use in the application. Even when others have long since given up.

Your contact persons

Thomas Mester

General Manager

0291 - 291 3120

thomas.mester@martinrea.com

Ingo Kotthoff

Head of Sales

0291 - 291 390

ingo.kotthoff@martinrea.com